Maritimo continues to press forward with its pre-production refinements of the latest additions to its glamorous line-up of luxury, long range vessels. The new M50 Flybridge Motor Yacht and S50 Sedan Motor Yacht embody everything that is truly Maritimo in a package whereby every square centimetre of the vessels has been reviewed and considered, leading to enhancements that will be enjoyed by future owners.

The many thousands of hours invested in planning, customer consultation, computer-aided design, and engineering development is starting to take form, with the hull currently in engineering and major hull, deck, and flybridge components a matter of weeks away. As the first hull starts to take its three-dimensional form in all its full-scale glory, now is the time in the process where design and engineering decisions made on screen are critically reviewed and further honed.

Neil McCabe, Maritimo’s Design Office Manager, along with Senior Designer Julian Villegas, have lived and breathed this development process over these last 24 months or so. A recent discussion with the Maritimo Design Team provides us with insights into the process and what will be delivered to the market when these magnificent vessels are launched globally in 2025.

“Well, we are showing customers now. We had a customer in on Friday, and they had a factory tour to view all the plug work that’s going on, and then our sales team brought them back up to the design office. We ran the customers through the full 3D model and showed them all the features. It’s a really useful communication tool that we have now, as we develop everything in 3D,” said McCabe.

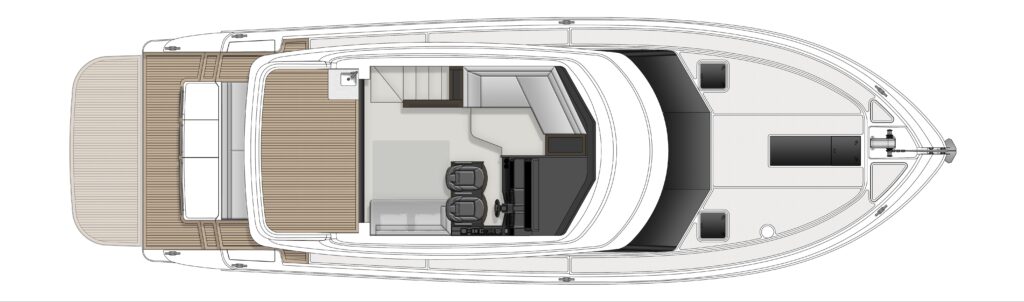

“Just being able to do all those sections through the boat, so people can see the different levels. The fact that we’ve got the cockpit as one level through to the galley, the customer loved that, and then we can show where we’ve been able to reduce the overall height of the boat to get the proportions of the boat lower down, because it is a shorter boat. We showed what we’ve been able to do with steps and to reduce the height of steps on the boat and yet not compromise the headroom throughout the vessel. We’ve maintained the minimum head height of 1.9m, which helps for safety and comfort, but also creates this feeling of openness and volume,” McCabe added.

“The Maritimo process gives a lot of comfort to customers when they actually are talking about putting their deposits down on a new boat that they actually haven’t walked on yet. So, they know what to expect in terms of fit out and they get a really clear idea of the design of the boat.”

“We’ve now had the ability, as the deck was being built, to fine-tune some of the details around the flow of people traffic. So, as you’re moving through the galley, up the stairs, we’ve tweaked some of the staircases around, we’ve tweaked the lounges around and changed the angle on the lounge just to make the flow better, from the saloon floor level up to the cockpit. These are the things that you don’t see on a computer screen. When you walk on the boat, it allows us to get a feel and get the ergonomics right. It’s all part of the process,” said McCabe

“Yes, you need to really experience it in full scale when designing and refining. You need to move through the vessel to feel those choke points and feel what works, as well. And it’s a different perspective to when we’re looking at the design on a computer screen, compared to being inside the space,” Villegas added.

“The master cabin is quite symmetrical, with the hanger lockers at the forward end. The size of the cabin itself is bigger than what you’d experience on a 55, 60, or 600. The hull windows are also longer than what you’d see on a 55 because they’re the full length of the cabin and just short of the hanger locker. You’ve also got forward and out-opening windows on both sides of the hull windows. We have cabinetry on the starboard side as standard. And on the port side, we have a day lounge, and then you’ve got your big ensuite there.”